CVD diamond microchannel cooling system for ultra-high heat flux chips

October20, 2025

CVD diamond microchannel cooling system for ultra-high heat flux chips

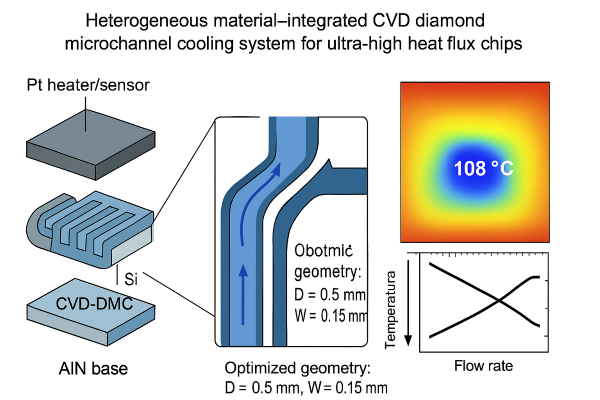

With the continuous increase in chip power density and integration, efficient thermal management has become a critical challenge. This study presents a heterogeneous material–integrated cooling system based on chemical vapor deposition diamond microchannels (CVD-DMCs) and evaluates its thermal performance under ultra-high heat flux through combined simulations and experiments.

Three rib geometries—rectangular, circular, and rhombic—were analyzed to optimize heat transfer and hydraulic behavior. The rhombic rib structure, with a rib depth of 0.5 mm and width of 0.15 mm, achieved the best performance, reducing the maximum die temperature to 108 °C under heat fluxes of 1100 W/cm² (dual large-area) and 11,000 W/cm² (multi-point small-area) at a flow rate of 144 mL/min, with a pressure drop of 11.22 kPa. Experimental results confirmed that rib width has a stronger influence on performance than rib depth.

The integrated Pt thin-film heaters enabled localized heating and in-situ temperature sensing, validating the accuracy of chip-level thermal mapping.

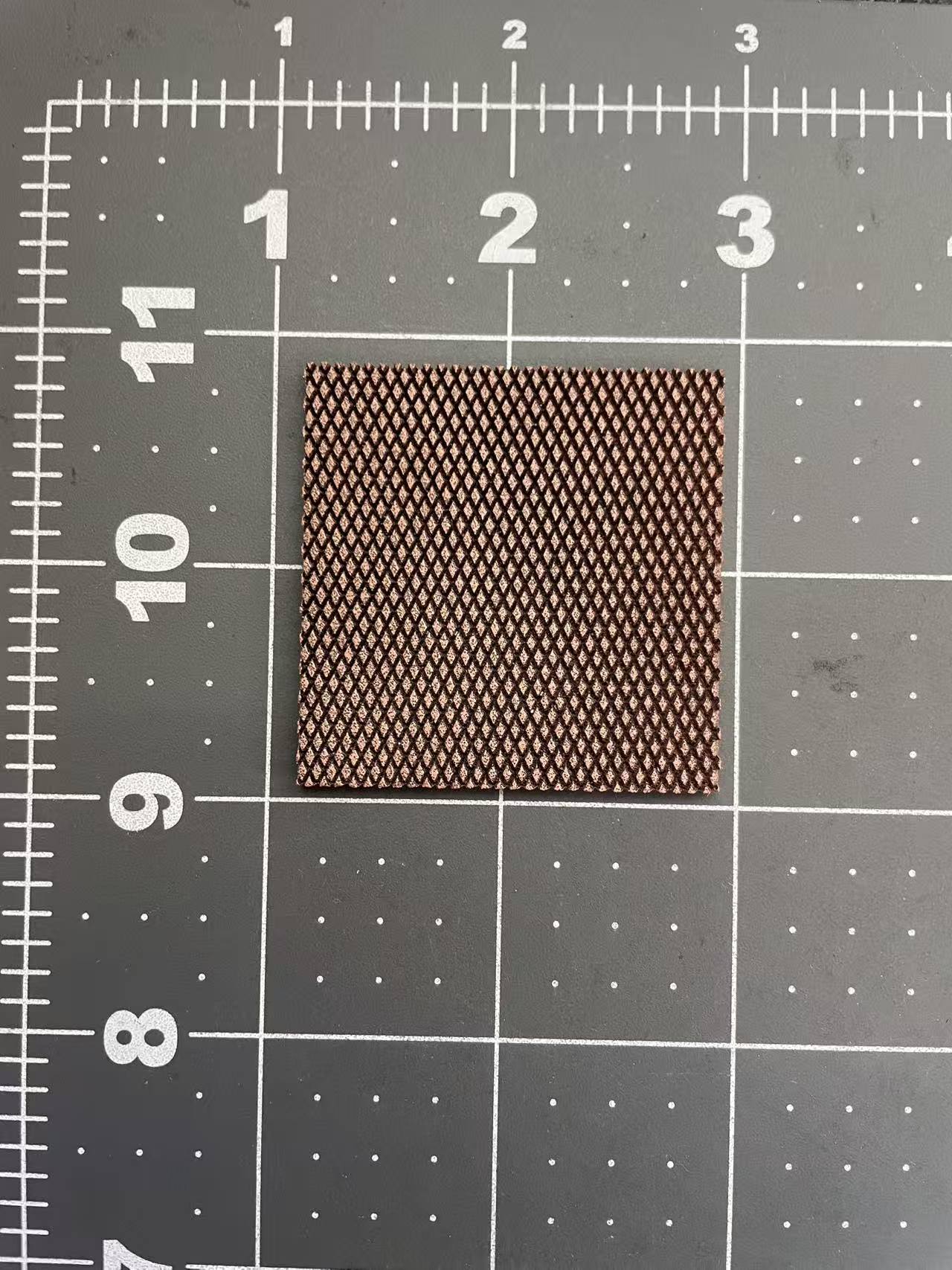

Diasemi rhombic shape diamond copper microchannel microfluid heatsink