High Density Diamond Copper Composite

July17, 2025

High-Density Diamond/Copper Composites

A high-density diamond/copper (diamond/Cu) composite with a high diamond volume fraction was fabricated through a combination of surface metallization, powder mixing, and spark plasma sintering (SPS). The process comprises the following steps:

Copper Electroplating on Diamond Particles:

Diamond particles pre-coated with a thin iridium layer were subjected to electrochemical deposition of copper. The mass of the deposited copper was controlled to be between 50% and 200% of the mass of the iridium-coated diamond, ensuring sufficient interfacial bonding and thermal continuity.Powder Mixing:

The copper-coated diamond particles were homogeneously blended with pure copper powder using mechanical mixing techniques to ensure uniform distribution of the reinforcement phase.Pre-Compaction:

The mixed powder was loaded into a graphite die and subjected to uniaxial pre-compaction to form a green body with initial structural integrity.Spark Plasma Sintering (SPS):

The pre-compacted samples were sintered using the SPS technique under controlled temperature and pressure conditions. This method facilitates rapid densification while minimizing grain growth and thermal degradation of the diamond particles.Post-Sintering Processing:

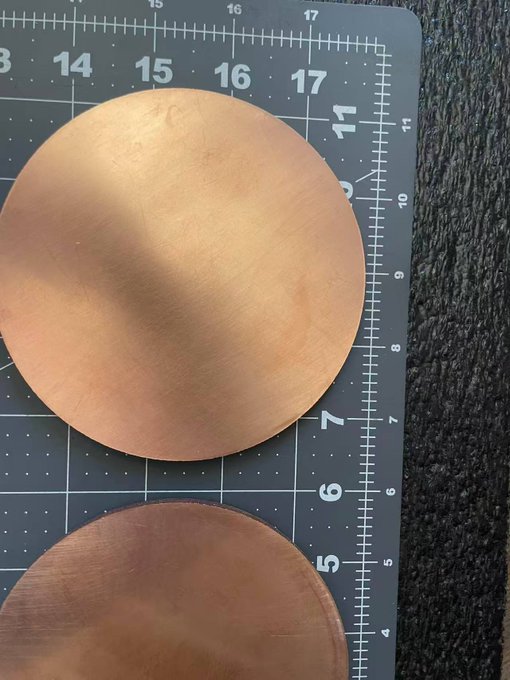

After sintering, the bulk composite was demolded, followed by cutting and surface polishing to obtain specimens for characterization.

The resultant diamond/Cu composites exhibited a relative density exceeding 99%, indicating excellent densification. This approach enables the incorporation of a high volume fraction of diamond while maintaining favorable thermal and mechanical properties. Furthermore, the process is cost-effective and scalable, making it suitable for industrial applications where high thermal conductivity and mechanical strength are required.